Benefits of using a thermo well:

Using a thermo well has several benefits, including:

- Protects temperature sensors from damage, corrosion, and high-pressure flow, thereby increasing their longevity and reducing the frequency of replacements.

- Provides a consistent and accurate temperature measurement, as the sensor is not in direct contact with the process medium, which could alter the temperature reading.

- Allows for easy maintenance of temperature sensors, as they can be replaced or removed without interrupting the process or shutting down the pipeline.

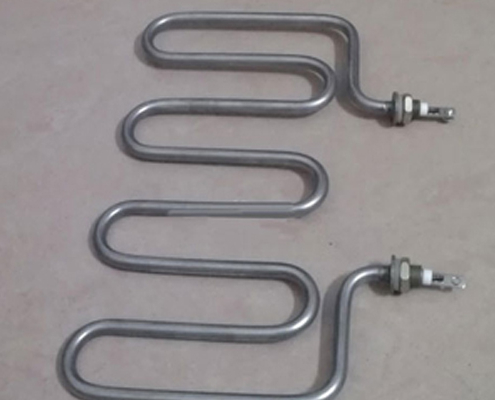

How does a thermo well work?

A thermo well is usually made of stainless steel, brass, or other materials that can withstand the harsh industrial environment. It is a hollow tube that is inserted into a pipeline or vessel, with the temperature sensor placed at the bottom of the tube. The space between the sensor and the tube is filled with a thermally conductive material, such as a ceramic or an epoxy, which helps to transfer the heat from the process medium to the sensor.

When the process medium flows through the pipeline, it comes into contact with the thermo well, which acts as a barrier between the medium and the sensor. The heat from the medium is transferred through the thermo well to the sensor, which accurately measures the temperature.